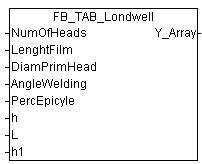

Alghoritm “FB_ TabLongDwell”

(computes the cam table profile of a LongDwell head)

The sealing head type "Long Dwell" provides a long segment of sealing and it is used in the horizontal and vertical flow pack machines.

The film sealing depends by three factors: time, pressure and temperature. If we are limited with temperature and pressure we need a long time for sealing.

The "LongDwell" profile fixes that problem forcing the sealing mass to cover a horizontal segment strictly contacting with film.

The LongDwell head is different from a rotative sealing head where the film is sealed only during a little angle.

The servomotor drives the shaft of the head with a gear box and must follow a particular cam profile in order that the horizontal component velocity of the mass sealing must be point by point equal to the film velocity.

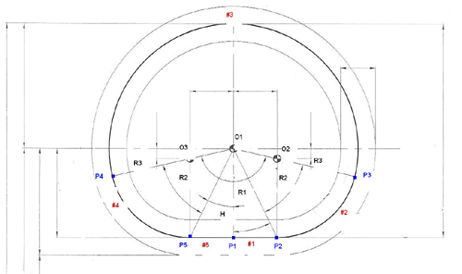

Reference Fig.1 (where is rappresented only one of the two heads) starting from point P1 where the two head are perfectly vertical mirrored , the cam profile is splitted in:

1. Segment P1-P2 horizontal with radius variable from H to R1 by centre O1.

2. Segment P2-P3 with radius R2 by centre O2. .

3. Segment P3-P4 with radius R3 by centre O1.

4. Segment P4-P5 wth radius R2 by centre O3.

5. Segment P5-P1 horizzontal with variable radius from R1 to H by centre O1.

(The segments are marked by colour blue points)

Follows that the cam profile is composed by five functions f1(x), f2(x),f3(x),f4(x),f5(x)with the following border conditions:

Into segments 1-2-4-5 horizontal velocity of the mass sealing must be equal to the film velocity.

The segment 3 is a simple connection.

All the segments must have the extremes continue in position, velocity and acceleration.

Depending of the product hight the interference angle between the head and film has the left extreme into P4-P5 and the right into P2-P3, follows that the condition of the velocity equal to film velocity must be true only into this angle.

The algorithm "FB_TabLongDwell" calculates the cam profile of the servomotor for "n" heads depending by the mechanic construction.

Tip of the day:

Basically must be introduced a "Epicycle" in % that means the following:

With epicycle=100 % the horizontal speed of the mass must be equal to the film velocity.Sometimes we prefer running with a epicycle of 95-97%.

After calculated the cam profile if you are obliged (to have the horizontal component velocity of the mass equal to the film velocity) to put an epicycle very different of 100% you are wrong and please,... recalculate all.

The algorithm "FB_TabLongDwell" is at disposal and written by structured language (IEC1131) in a function block with "n" inputs and "m" outputs. (see below)

At to day this function block is available in version:

ELAU, Rockwell Automation, Siemens, Indramat, B&Rand any other systems that uses language IEC1131.

Please, contact: fabiano.manzan@art-of-motion.it

Fig.1

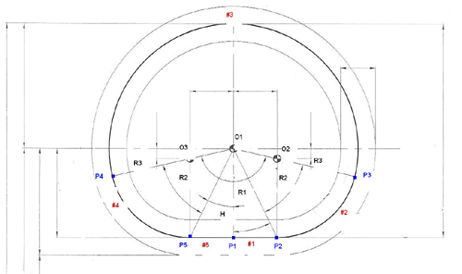

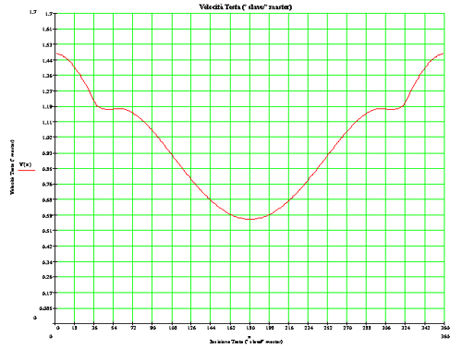

In Fig.2 e Fig.3 are showed the position and velocity of the shaft (servomotor) for:

film lenght less then primitive developed from one head and the following head.

Fig. 2

Fig. 3

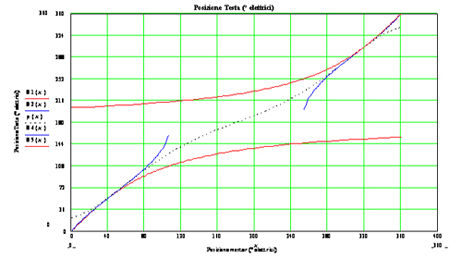

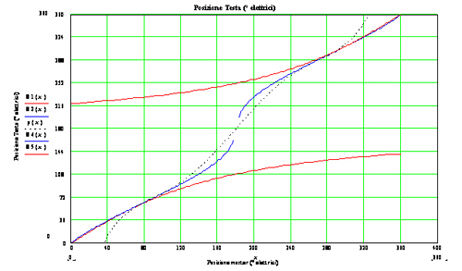

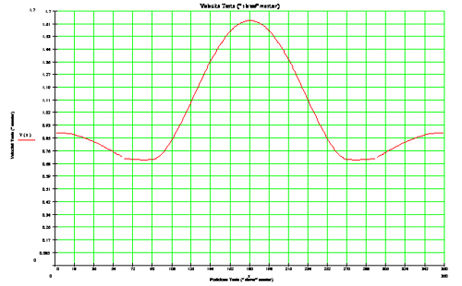

In Fig.4 e Fig.5 are showed the position and velocity of the shaft (servomotor) for:

film lenght greater then primitive developed from one head and the following head.

Fig.4

Fig. 5

“FB_ TabLongDwell ” :